JR Plastics and Machining, Inc.

CNC Machining and Custom Vacuum Forming throughout North America

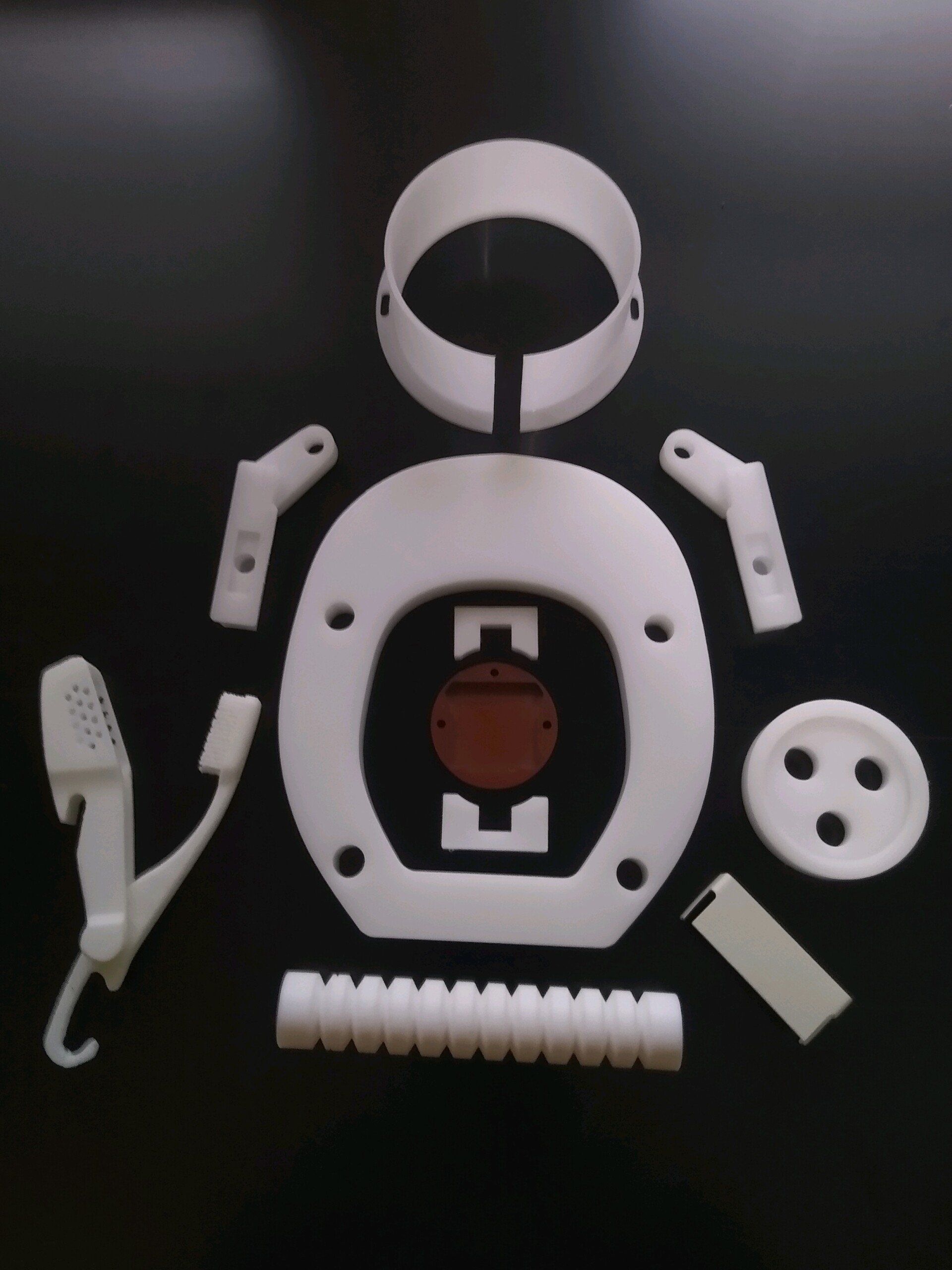

Professional Vacuum Forming

Since 1994, JR Plastics & Machining, Inc. has provided custom vacuum forming for North America. Utilizing reliable and accurate equipment, we produce quality parts with very little down time.

For a more in-depth description of Vacuum forming, see the Question section at the bottom of the page.

The Entire Production Process Under One Roof

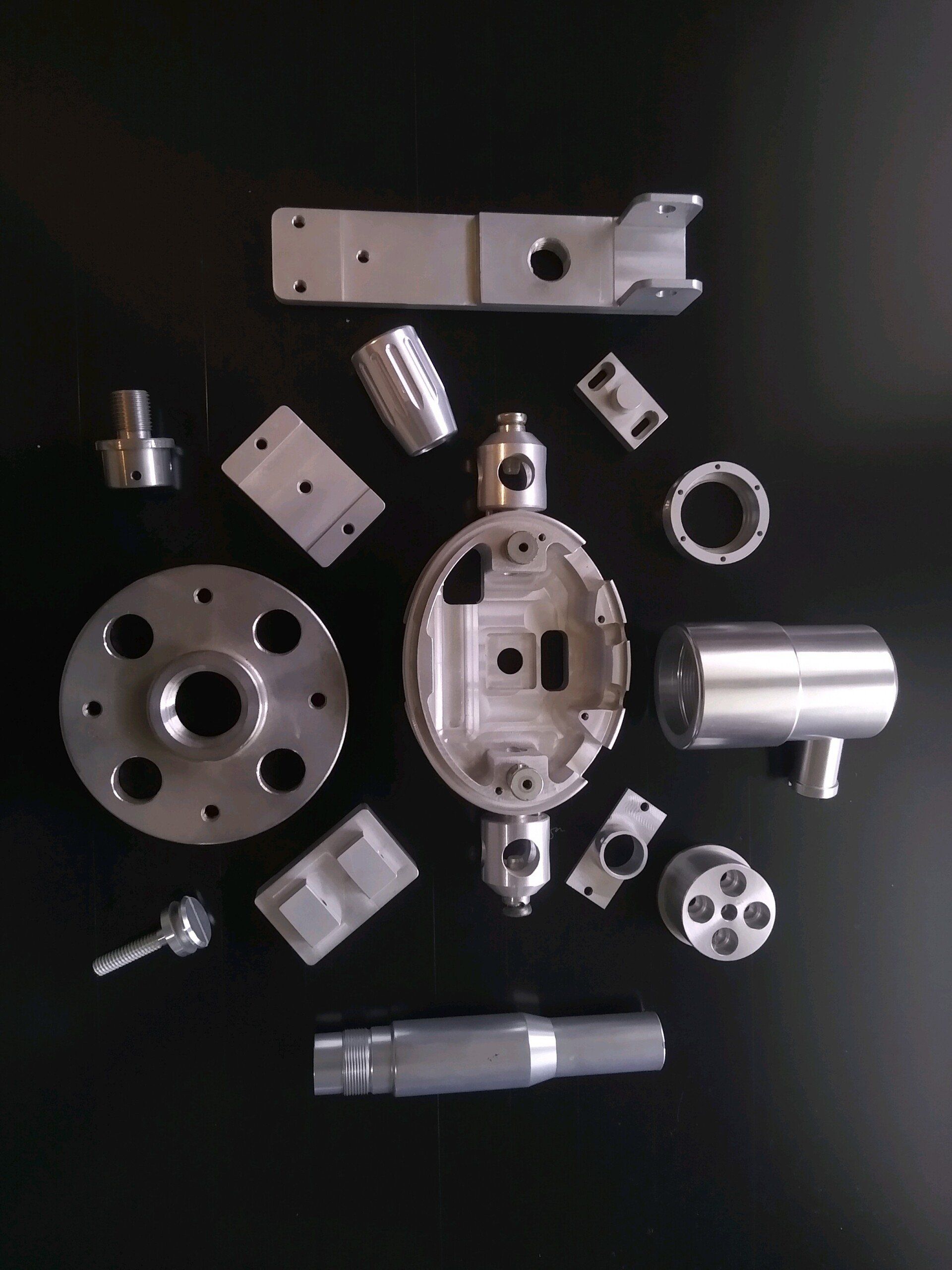

When you choose JR Plastics & Machining, Inc., you work directly with one of our owners from start to finish. We go over the production process with you and can engineer your product's design for optimal performance and cost-efficiency. Our services include custom vacuum forming, hotwire bending, and CNC machining.

Our In-House Equipment and Product Capabilities

For custom vacuum forming, we can form parts as large as 24" x 50" x 9" deep in plastics up to 0.250" thick. We can form PETG, PVC, ABS, Polycarbonate Kydex, Polystyrene, Acrylic, HDPE, and more. For machining, parts as big as 50" x 100" x 9" thick in alloys, including aluminum, brass, and stainless steel.

Serving Nationwide

JR Plastics & Machining, Inc. has over 100 years of collective experience in vacuum forming, hotwire bending, and CNC machining. We look forward to working with you on your next project,